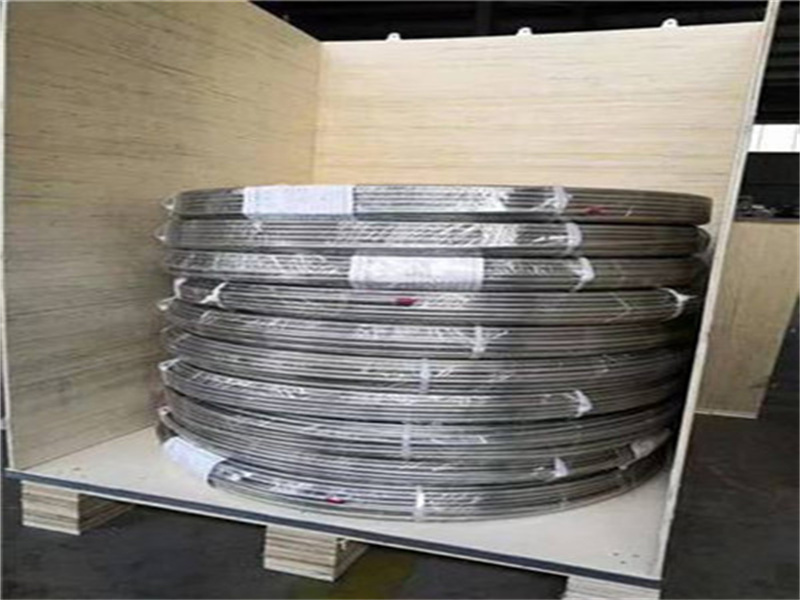

304L / 1.4307 Stainless steel capillary coiled tubing

The stainless austenitic chromium-nickel steel 1.4307 has good corrosion resistance (especially in natural environmental media and during absence of significant chlorine and salt concentration and sea water) and weldability. Check applications with acids specifically. In welded condition 1.4301 is not resistance to intergranular corrosion.

Material Data Sheet

| Material Designation | 1.4307 |

| AISI/SAE | 304L |

| EN Material Symbol | X5CrNi18-10 |

| UNS | S 30400 |

| ANFOR | Z7CN 18-09 |

| B.S. | 304 S15 – 304 S31 |

| Norm | EN 10088-3 |

Main fields of application of 1.4307

1.4307 is well to be polished and thermoformed. It is mainly used in chemical industry, petroleum, petrochemical and automotive industries.

Chemical composition of 1.4307

| C | Si | Mn | P | S | Cr | Ni | N |

| ≤ % | ≤ % | ≤ % | ≤ % | ≤ % | % | % | ≤ % |

| 0.03 | 1,0 | 2,0 | 0,045 | 0,015 | 17,0-19,5 | 8,0-10,5 | 0,11 |

Characteristics of 1.4307

| Temperature Range | Density | Hardness (HB) |

| Since susceptibility to precipitation of chromium carbides, | 7,9 kg/dm³ | 160-190 |

| operating temperature of 450 ° C – 850 ° C to be carefully considered | ||

| (DIN EN 10088-3) |

Filler metal (for welding with 1.4307)

1.4316 (308L), 1.4302, 1.4551

Delivery program

Sheets / Plates mm

0.5 – 50

Coils mm

0.5 – 3

Precision strip mm

0.2 – 0.5

Write your message here and send it to us