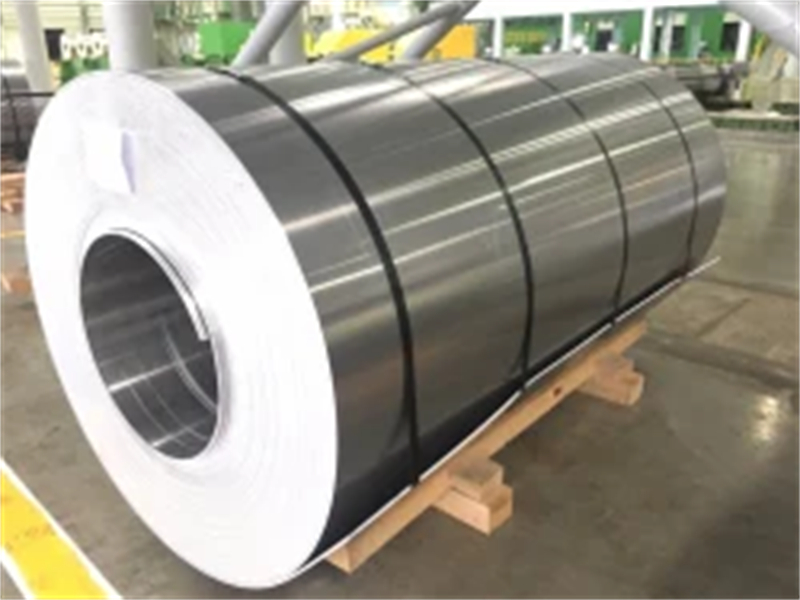

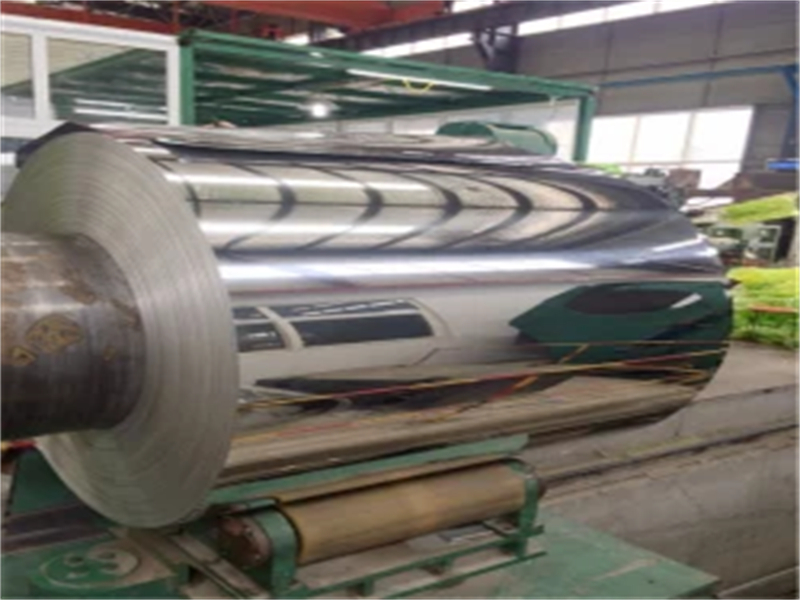

A1050 A1100 A3003 A3105 A5052 PE Coated Aluminum Coil and Sheet Roll suppliers

A1050 A1100 A3003 A3105 A5052 PE Coated Aluminum Coil and Sheet Roll suppliers

Aluminum has an outstanding strength-to-weight ratio and is easy to form. Its natural corrosion resistance, which can be increased with anodizing, is one of the biggest benefits. Aluminum coil is found in a range of applications from housing siding, trim, gutters, and roofing to cans, lids, caps, bottles, and other food packaging, appliances and electronics. Because it is a lightweight and durable material, it is also seen in the automotive industry.

Aluminum coil classification according to different alloy elements

1000 Series

1050 aluminum coil and strip

Features: 99.5% aluminum content, high plasticity, corrosion resistance, good conductivity and thermal conductivity, but low strength, not strengthened by heat treatment, poor machinability, acceptable for contact welding and gas welding. The production process is relatively simple and the price is relatively cheap

| Thickness (mm) | 0.10-6 |

| Width (mm) | 100-2500 |

| Temper | H18 |

1060 aluminum coil and strip

Features: the aluminum content of 1060 aluminum coil is 99.6%. 1060 aluminum coil has good elongation and tensile strength, and high formability.

| Thickness (mm) | 0.10-0.3 |

| Width (mm) | 100-2500 |

| Temper | O, H18, H22, H24 |

1070 aluminum coil and strip

Features: the aluminum content of 1070 aluminum coil is 99.7%. 1070 aluminum coil has the characteristics of high plasticity, corrosion resistance, good conductivity and thermal conductivity. Because of these advantages, 1070 aluminum coil is mostly used to manufacture some structural parts with specific performance, such as electric wire, cable protection net, wire core and aircraft ventilation system parts and decorations.

| Thickness (mm) | 0.10-6 |

| Width (mm) | 100-2500 |

| Temper | O, H18, H22, H24 |

1100 aluminum coil and strip:

Features: the aluminum content of 1100 aluminum coil is 99%. Because of its small density and good plasticity, it is usually used for parts that need good formability, high corrosion resistance and do not require high strength, such as sheet metal products, hollow hardware, radiator, welding combination keys, reflectors, nameplates, etc.

The coils are suited to our production line so 1000 mm or 3 foot (914 mm) wide as standard. The thickness ranges from 0.4mm up to 1.2mm with typical weights from 1 to 2 tonnes. Other alloys and tempers are available.

In addition we also offer small coils also described as Aluminium insulation coils. These have thickness between 0.3 – 2mm and width between 1000mm – 1250mm, with two different finishes: stucco or mill finish. The large range of alloys offer exceptional formability, corrosion resistance, toughness and mechanical properties to resist mechanical or thermal abuse in service. These are used, for many applications including, for refrigeration and heat insulation installers for coating boilers, pipes, ducts and other parts of the installation. These are typically produced in sizes such as 125 kgs or 150 kgs but generally produced to clients requirements.

Due to our large demand for processing we have excellent supply routes for our coils this means that if we don’t have immediate availability or enough stock we can source in around 1-4 weeks. As well as plain or smooth finish Aluminium we also keep stucco embossed coils or can supply painted or laminated. All our coils can either be reduced in weight to suit the clients processing capabilities, cut into sheet or precision slit into narrow coils. We can even convert them into corrugated sheets.

Many of our coils are laminated to order with Surlyn moisture barrier for use as metal jacketing, Tedlar (PVF) outer coating, coil painted PVDF, PES,PUR or bonded with a mass loaded vinyl acoustic barrier for ease of application when sound reduction is required. In addition we can also offer other specialist laminates including PVF or PVC including anti-bacterial coatings or grain effect.

We also keep a range of other products to fix or aluminium coils including banding, wing seals, rivets and toggle latches, self drilling (TEK) screws.

If you have a requirement for Aluminium coil or cut to length non standard sheet sizes as blanks then speak to our sales team.