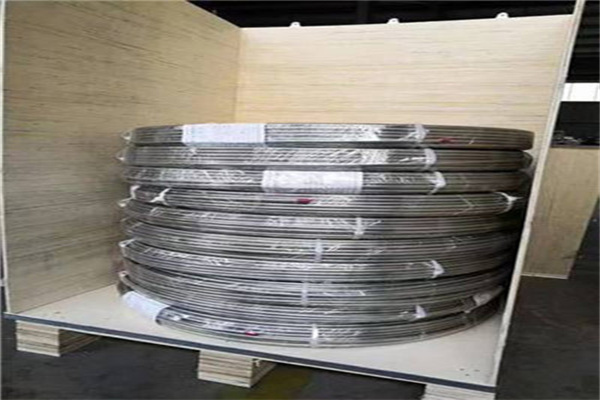

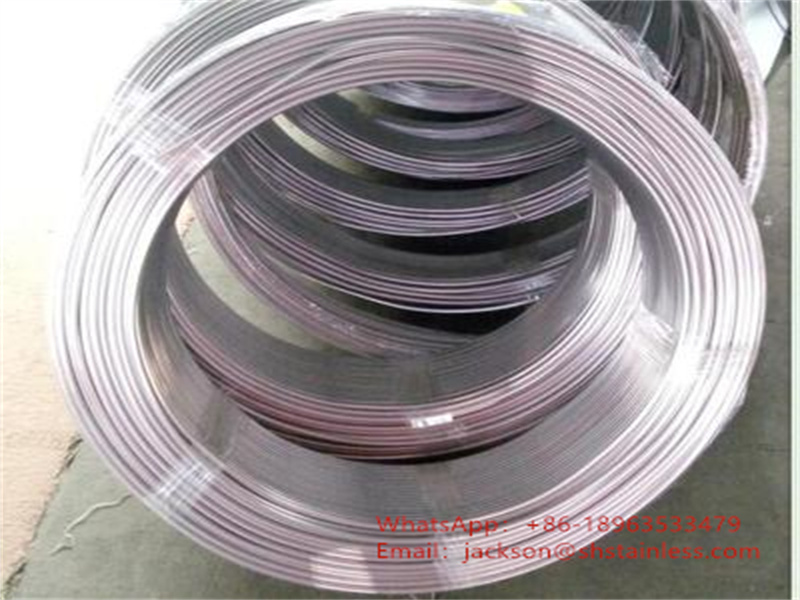

ASTM A213, A269 904L stainless steel coiled tubing in China

Alloy 904L is a non-stabilized, high alloy austenitic stainless steel with low carbon content. It is widely used in applications where the corrosion properties of TP316/L and TP317/L are not adequate. The alloy also offers excellent formability, weldability, and toughness. The addition of copper gives alloy 904L corrosion resistant properties that are superior to the conventional chrome nickel stainless steels. Examples include resistance to sulfuric, phosphoric, and acetic acids.

Size Range

| Outside Diameter (OD) | Wall Thickness |

| .250”–1.000” | .035″–.065″ |

Cold finished and bright annealed tube.

Chemical Requirements

Alloy 904L (UNS N08904)

Composition %

| C Carbon |

Mn Manganese |

P Phosphorus |

S Sulfur |

Si Silicon |

Cr

Chromium |

Ni

Nickel |

Mo Molybdenum |

N Nitrogen |

Cu Copper |

| 0.020 max | 2.00 max | 0.040 max | 0.030 max | 1.00 max | 19.0–23.0 | 23.0–28.0 | 4.0–5.0 | 0.10 max | 1.00–2.00 |

Dimensional Tolerances

| OD | OD Tolerance | Wall Tolerance |

| ≤ .500″ | ± .005” | ± 15% |

| 0.500”–1.500” | ± .005” | ± 10% |

Mechanical Properties

| Yield Strength: | 31 ksi min |

| Tensile Strength: | 71 ksi min |

| Elongation (min 2″): | 35% |

| Hardness (Rockwell B Scale): | 90 HRB max |

Fabrication

Alloy 904L is non-magnetic in all conditions and has excellent formability and weldability. The austenitic structure also gives this grade excellent toughness, even down to cryogenic temperatures.

Industry Applications

Chemical Process

Its high chromium and nickel content, along with the addition of molybdenum and copper, help alloy 904L stand up to sulfuric, phosphoric and acetic acids. This is especially useful in the production of acids and fertilizers.

Write your message here and send it to us