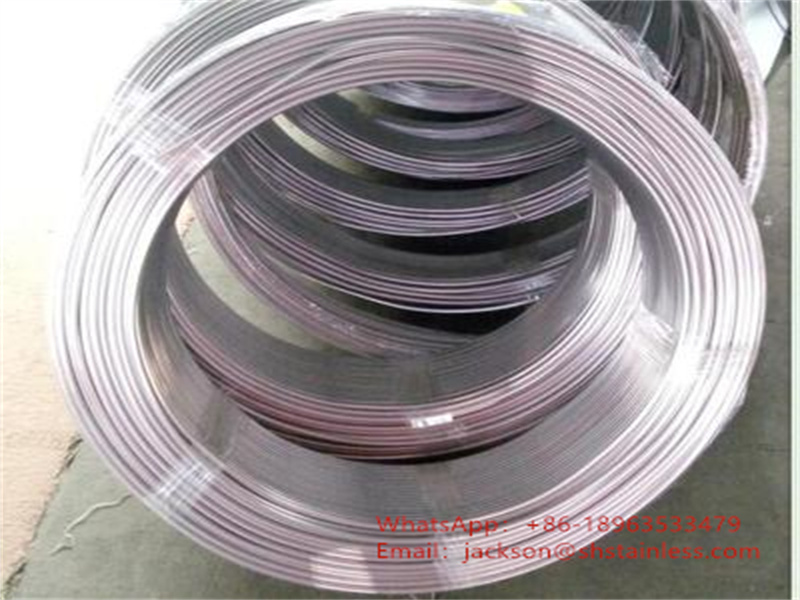

904L 9.52*1.24mm Stainless steel coiled tubing suppliers

Specification

904L 9.52*1.24mm Stainless steel coiled tubing suppliers

| Steel Grade | 904L |

| Standard | |

| OD range | Seamless:12-377mm

Welded:10-2000mm |

| WT range | Seamless:1-30mm

Welded:1-40mm |

| Length Range | 4-9meter; Random Length; Fixed Length |

| Forming | Hot finished; Cold Rolled; Cold Drawn; ERW welded |

| Heat-treat | Solution |

| Surface | Acid Pickled; Polished |

| Inspection | Chemical; Tensile; Hardness; UT; Eddy Current |

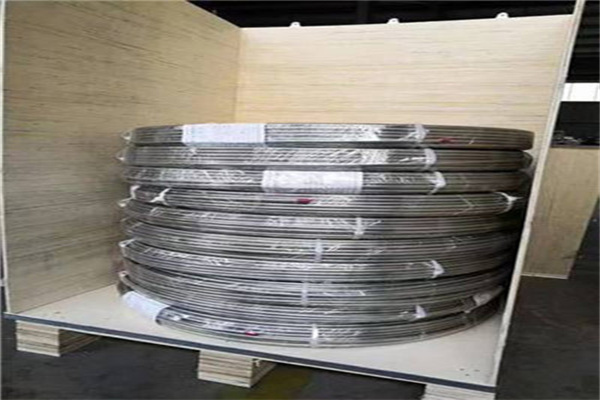

| Package | Steel rope or wooden case |

| MOQ | 1 tons |

| Delivery Time | 10-30 days |

| Trade Item | FOB CIF CFR PPU PPD |

alloy 904L tubing (UNS N08904) for use in applications that require moderate to high corrosion resistance. Alloy 904L is a low carbon high alloy austenitic stainless steel, originally developed to resist corrosion in dilute sulfuric acid. Because of the combination of chromium, nickel, molybdenum and copper, this grade has greatly improved resistance to strong reducing acids, particularly sulfuric acid. Alloy 904L tubing is also extremely resistant to chloride attack from both pitting/crevice corrosion and stress corrosion cracking. Alloy 904L is non-magnetic in all conditions, possesses amazing toughness, and has good formability and weldability.

Because of these properties, one can find alloy 904L tube in many applications. These range from utility scrubber assemblies to acid and fertilizer production equipment, pulp and paper processing, seawater cooling facilities. Used in processes containing sulfuric or phosphoric acids, 904L displays its excellent resistance to corrosion from those acids. The paper, gas, pharmaceutical and chemical industries also use 904L for its resistance and use to 400-450 degrees C. Alloy 904L tubing can be welded, machined, heat treated, annealed, hardened and cold worked for many purposes.

UNS NO8904, commonly known as 904L, is a low carbon high alloy austenitic stainless steel which is widely used in applications where the corrosion properties of AISI 316L and AISI 317L are not adequate.

The addition of copper to this grade gives it corrosion resistant properties superior to the conventional chrome nickel stainless steels, in particular to sulphuric, phosphoric and acetic acids. However, there is limited use with hydrochloric acids. It also has a high resistance to pitting in chloride solutions, a high resistance to both crevice and stress corrosion cracking. Alloy 904L performs better than other austenitic stainless steels due to the higher alloying of nickel and molybdenum.

The grade is non-magnetic in all conditions and has excellent formability and weldability. The austenitic structure also gives this grade excellent toughness, even down to cryogenic temperatures.

The high chromium content promotes and maintains a passive film which protects the material in many corrosive environments.904L has a greater resistance to precipitation of ferrite and sigma phases on cooling and welding than other stainless steels containing molybdenum such as 316L and 317L. There is no risk of intercrystalline corrosion on cooling or welding due to the low carbon content. Its maximum service temperature is at 450°C.

This grade is particularly useful in control and instrumentation tubing applications where 316 and 317L are not suitable.

904L stainless steel combines molybdenum and copper with iron for tremendously increased resistance to reducing acids like sulphuric acid. It stands up extremely well to chlorides in the environment for low pitting and crevice corrosion, as well as stress corrosion cracking.

904L Stainless Steel Pipes and Tubes Product Range 904L Stainless Steel Pipes and Tubes Specifications: ASTM A/ASME SA 269/677 904L Stainless Steel Pipes and Tubes Sizes (Seamless): 1/2″ NB – 8″ NB 904L Stainless Steel Pipes and Tubes Sizes (ERW): 1/2″ NB – 24″ NB 904L Stainless Steel Pipes and Tubes Sizes (EFW): 6″ NB – 100″ NB

»904L Stainless Steel Pipes and Tubes Dimensions: All Pipes is manufactured and inspected/tested to the relevant standards including ASTM, ASME and API etc. Key Properties These properties are specified for flat rolled product (plate, sheet and coil) in ASTM B625. Similar but not necessarily identical properties are specified for other products such as pipe, tube and bar in their respective specifications.

Applications

904L stainless steel is widely used in the chemical, pharmaceutical, oil and gas industries. Typical applications include tanks, valves, heat exchangers, flanges and manifolds. The addition of copper to the composition of 904L stainless steel aids its suitability for components such as tanks and other products used in handling sulphuric and phosphoric acid.